McFir7

Club Guest

- Joined

- Jun 4, 2006

- Messages

- 362

- Points

- 18

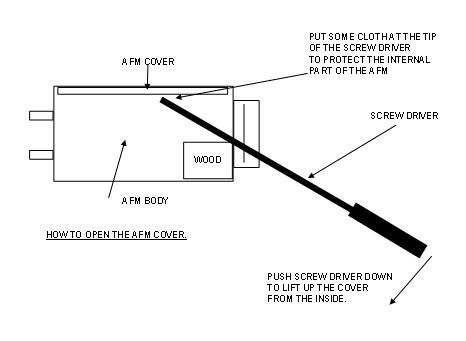

today i decided to clean up my afm as i seen someone posted here on how to open n clean it..i try to open the bottom metal cover but i failed..the screws it too tight in,i have try using wd40 but i doent work.so i decide to leave that to mechanic to help me out as my afm is nvr been open in anyways..so since i cant do that,i move on to clean the inside air goin thru tunnel.i did some sand paper in it.now is smootly flapping than b4.but the i feel the tension is bit hard..so what i did was pop up the black top cover n clean it..also turn right(anti clockwise) by only one click..fix all back..driving around at low n high speed seems to be better n more responsive.but i would like to know do anyone here know how to set the flap at the best tension.i was searching on net mostly only shows bout the afm like m20 (the ones have screw at the top to adjust the air fuel ratio).what i was lookin for how to adjust the best tension flap..any idea guys?thank u..