sunnypuan

Club Guest

- Joined

- Dec 7, 2009

- Messages

- 624

- Points

- 0

bimmer73;541199 said:To the culprit you are a bird brainer......please pm me when you people gat crash his place............

Great...supporters building up here...:top: Will do, Bro ! !

bimmer73;541199 said:To the culprit you are a bird brainer......please pm me when you people gat crash his place............

E28driver;541423 said:I have no relation to M Speed, but could they not have acquired the seals from some other source legitimately?

E28driver;541423 said:I have no relation to M Speed, but could they not have acquired the seals from some other source legitimately?

kayzhen911;541614 said:yo herb....

when can stk be available once paid?

LightingStrike;542000 said:Herbert,

The Feed back from the BMW workshops regarding the Beisan issue. Is you plot to get forumers (customers) to your workshop. Thats why the Beisan collection center is your workshop.

I met up with a few BMW workshop including M Speed, Naidu, Chien USJ & etc..They mention you off & on goes to their workshop soliciting for customers for your own workshop by collection contact information form awaiting customers and telling here they charged very expensive, this made them very pissed off with you.

The Beisan Seal has been around for sometime surprising feed back I m getting the workshops people is that you make more then 50% margin from selling the seals in the forum group buy.

Another incident Workshop A helped you to rectified your customer's E90 central locking issue for free which your mechanic cant solve without any charges! Then you going around saying Workshop A charged you RM 150/= Probably you charged that amount to your customer.

Business is business but going around and bad mouth your competitions is not the right way to do business.

LightingStrike;542000 said:Herbert,

The Feed back from the BMW workshops regarding the Beisan issue. Is you plot to get forumers (customers) to your workshop. Thats why the Beisan collection center is your workshop.

I met up with a few BMW workshop including M Speed, Naidu, Chien USJ & etc..They mention you off & on goes to their workshop soliciting for customers for your own workshop by collection contact information form awaiting customers and telling here they charged very expensive, this made them very pissed off with you.

The Beisan Seal has been around for sometime surprising feed back I m getting the workshops people is that you make more then 50% margin from selling the seals in the forum group buy.

Another incident Workshop A helped you to rectified your customer's E90 central locking issue for free which your mechanic cant solve without any charges! Then you going around saying Workshop A charged you RM 150/= Probably you charged that amount to your customer.

Business is business but going around and bad mouth your competitions is not the right way to do business.

LightingStrike;542120 said:Guys,

Just go to M Speed and the other workshops with Herbert..

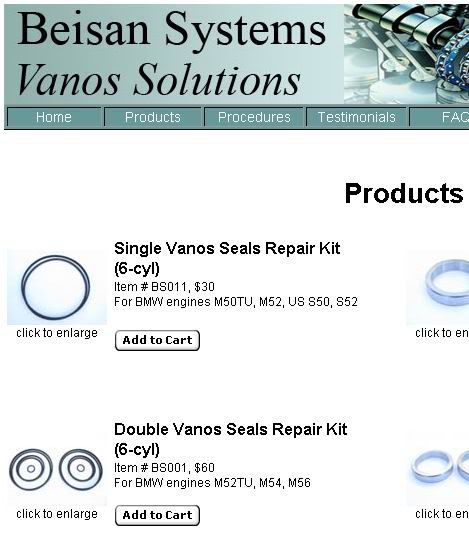

Beisansystems;541396 said:Hello everyone. I’m Rajaie, owner and president of Beisan Systems.

As you know Herbert has been in contact with me and has arranged a few group buys for this forum. I’d like to first thank Herbert for his extraordinary efforts and the forum members for their interest in the Beisan products. I hope everyone who has installed the Beisan products has received performance benefits and is pleased with their results.

Herbert has made me aware of this post thread and the company M Speed who has indicated they are providing vanos seals products. On this thread there is a picture of the seals product they are providing and it’s of the Beisan Systems product packaging. I have looked through our sales database and have noted that only Herbert is engaged in volume purchases from Malaysia. M Speed is not in contact with me and is not purchasing Beisan products. I’m disappointed to see that they seem to claim to be providing Beisan products.

The vanos seals are a semi-standard dimensional design. They are not readily available but can be manufactured. Although the dimensions are semi-standard the material makeup is not. There are many material types and grades of the seals, particularly the Teflon rings. Although the OEM Teflon rings are not failing they need to be removed and replaced to access the underneath failing rubber O-rings. Teflon is not used in its virgin form. Fillers are added to increase resistance to wear and deformation. The OEM Teflon rings have a carbon filler. We initially made the Teflon rings from a standard carbon filler but had many problems. The seals would take ~500 city miles to break-in. There can be very rough running at first. There can be codes and in some cases serious codes that would make the car not drivable. We investigated this matter and assessed the standard carbon materials did not work well for the vanos application. The vanos is made of soft aluminum and uses low oil pressure (compared to the thousands of PSI oil pressure used on standard hydraulic applications). After some investigation with a seals materials company we decided to use the OEM high grade expensive Teflon filler. When we first did this our in volume manufacturing costs went up by 40%. The OEM Teflon material is fairly exclusive and not readily available. Switching to the OEM Teflon material resolved the problems we were encountering. We have since also had our seals manufacturer polish the Teflon rings to reduce the seals break-in period and provide performance benefits faster.

We have inspected our seals at 15k and 30k miles. They are in excellent condition. The Teflon rings are highly polished and the O-rings are fully elastic and resilient. The vanos cylinder walls are also highly polished and not damaged. Everything is in excellent condition. We expect the seals to last the life of the car.

We have provided thousands of these seals kits to owners in many countries over the past 3 years and have not had a single case of failure.

Last year we introduced vanos rattle kits. These address the vanos rattle that can be found on some cars. The rattle kits have also been quite popular and successful.

We are developing seals and rattle kits for the Euro S50 engine single and double vanos units (Euro E36 M3). We are developing a rebuilt vanos solenoid pack for the S54 engine vanos failure (E46 M3). We are developing a vanos rattle kit for the S62 engine (E39 M5). We will be developing a vanos rattle solution for the V8 M62TU engine (E39 540 & E38 740).

I hope some of this info is helpful to owners on this forum.

Again thank you for your interest in the Beisan products. I hope many of you regain your car's full potential by installing the products.

Special thank again to Herbert for arranging the group buys that allow this forum to acquire the Beisan products in an efficient and cost effective manner.

Best,

Rajaie

Rajaie Qubain (Raj), President

Beisan Systems LLC (bee-saan), www.beisansystems.com

2109 Longwood Drive, Raleigh, NC 27612

rajaie@beisansystems.com, W (919) 676-1939, M (919) 345-2000